Natural Gas Compressors

What Is a Natural Gas Compressor, and How Does It Work?

A natural gas compressor increases the pressure of a gas by reducing its volume. The natural gas enters the cylinder through the intake valves, where it is compressed and forced out through discharge valves. A gas air compressor is one form of natural gas compressor that is used in a wide range of industrial applications where either high pressure or lower volumes of gas are required. Examples include:

- Petroleum refineries, natural gas processing plants and chemical plants: Used for the compression of intermediate and end-product gases

- Industrial manufacturing and building: Provides compressed air that powers various pneumatic tools and equipment

- Pipelines: Transporting natural gas from the production site to the end user

CB Process Instrumentation & Controls is a proud Quincy Royal Channel Partner. This makes us the sole distributor 100% covered by factory warranties in Western Canada and gives us the ability to offer our customers extended warranty programs on our Quincy Compressor products.

Quincy QRNG Reciprocating Gas Compressor

Description & Features

A reciprocating gas compressor uses crankshaft-driven pistons to provide compression. The thrust is provided by a positive displacement pump that moves the gas through the system and enhances the gas’s pressure and density. Benefits of reciprocating gas compressors include their ability to produce high power and high pressure compressed gas, as well as the absence of an oil carryover problem. Reciprocating compressors also generally require a lower initial investment than other compressor types.

- 2-34 hp

- Single & Two-Stage

- 400 psig max discharge

Do you require a different solution? Please visit the manufacturer's website for more products!

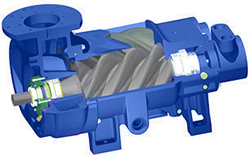

Quincy Compressor Official SiteQuincy QSG Rotary Screw Gas Compressor

Description & Features

A rotary gas compressor operates via positive displacement. It contains a pair of helical screws that drive the gas into a chamber. The screws simultaneously shrink the chamber, which forces the compression. These rotary screw compressors are known for their compact yet robust design and construction, as well as their reliability. However, rotary screw compressors are not suited for a dirty operating environment, and the rotary compressor’s life expectancy is typically shorter than that of a reciprocating model.

- 16 models to 600 hp

- Flows to 4.0 MMSCFD

- 130,000 hour design life