Innovative Continuous Gas Analyzers Technology

Reliable gas analysis — even under harsh process conditions

Extractive gas analyzers are used in a large number of industrial processes to measure everything from major gas concentrations to the smallest of trace contaminants. The extractive measurement technology extracts a partial gas flow from process and through a sample system, prepares it for analysis. Using various sensor technologies the analyzer is able to distinguish a component and accurately measure its concentration.

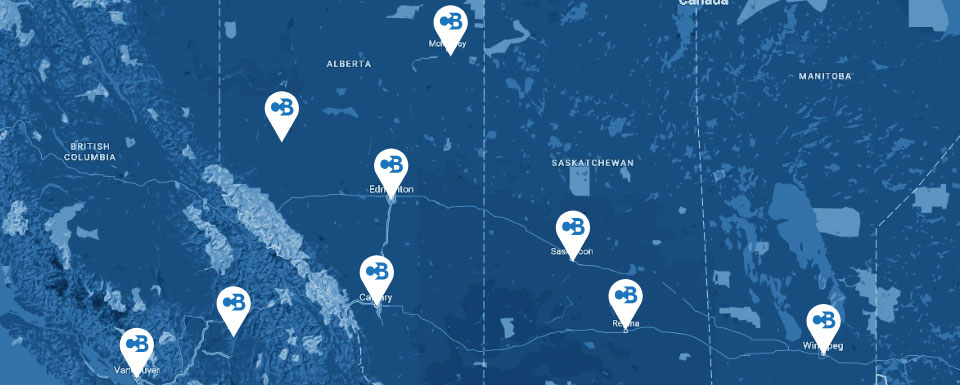

CB Analyzer Shelters

Description & Features

- Sample Points

- Sample Systems

- Analyzer Shelters

- Commissioning and Start-up

- On-going maintenance

- Shut-down serivce

SICK GM 32 In-Situ Process Gas Analyzer

Description & Features

Real-time gas analysis directly within the process

Innovative measurement technology that allows the devices to be mounted directly at the measurement site: In-situ gas analyzers take measurements directly within the process under system conditions. These analyzers are primarily characterized by their minimal maintenance requirements and extremely short response times. SICK’s in-situ gas analyzers are available in two different versions:

The cross-duct version for representative measurement results across the entire duct diameter

The measuring probe version, optimized for single-sided gas duct installation

At a glance

- Direct, fast in-situ measurement

- No gas sampling, no gas transport, no gas conditioning

- Up to eight measuring components at the same time, plus process temperature and pressure

- DOAS and CDE evaluation process

- Numerous independent measuring ranges with consistent accuracy

- Automatic self-test function (QAL3) without test gases

- Overpressure encapsulated design for ATEX Zones 1 and 2

- Measured values in real time without altering the gas composition

- Short-term process deviations are detected

- Representative measurement byselection of cross-duct or measuring probe versions

- Fast on-site service due to modular design

- Long maintenance-free intervals

- Cost-effective in-situ gas analyzer — also in ATEX design

- Low cost of installation and operation, no test gases required

- Complete emissions measurement in Kraft pulp process by way of simultaneous measurement of TRS components plus SO2, NO, NH3

Do you require a different solution? Please visit the manufacturer's website for more products!

SICK Official WebsiteSICK GMS800 Multi Component Gas Analyzer

Description & Features

- 6 different analyzer modules: DEFOR (NDUV, UVRAS), MULTOR (NDIR), OXOR-E (electrochemical O2), OXOR-P (paramagnetic O2), THERMOR (TC), and UNOR (NDIR)

- 4 different types of enclosures

- Gas module with sample gas pump and/or control sensors

- New enclosure type for easy and quick integration in analyzer systems

- Remote diagnosis via Ethernet with SOPAS ET software

- Approved according to EN 15267 and EN 14181

- Installations in Non-Ex-areas and Ex-areas (Zone 1 and 2 according to ATEX) possible

- Minimum service and maintenance work as well as easy reconditioning of existing installations due to modular design

- Adjustment without test gases via optional adjustment unit

- Minimal influence of ambient temperature through thermostatic controlled modules

- Reliable measuring results by proven measurement technology

- Easy maintenance and repair due to replacement of complete assemblies or modules

Do you require a different solution? Please visit the manufacturer's website for more products!

SICK Official WebsiteSICK TRANSIC100LP TDLS Oxygen Analyzer

Description & Features

- O2 transmitter based on high-performance laser spectroscopy (TDLS)

- For use in use in explosion-hazardous areas (FM, ATEX and IECEx approvals)

- Measurement directly in the process or extractive using a measurement gas cell (option)

- Designed for heavy-duty industrial applications

- Compact design and easy to operate

- Long-term stability

- No moving parts

- Measures in real-time directly in the process

- Easy installation and operation

- Self-diagnostics with maintenance display

- Low requirements for gas conditioning

- Low operating costs: no consumables and no purging gas consumption

- Rugged: reliable measurement even in contaminated gases

Do you require a different solution? Please visit the manufacturer's website for more products!

SICK Official WebsiteSICK Zirkor200 Combustion Oxygen Analyzer

Description & Features

- Measurement cell with extremely long service life due to innovative protection mechanism

- Measurement cell self-monitoring

- Fully automated adjustment mechanism integrated into the control unit

- Version for high temperatures available

- ZIRKOR remote app for remote access to analyzer

- Very short response time

- Suitability-tested according to EN 15267

- Easy connection of process control systems

- Very high availability due to measurement cell with extremely long service life

- High reliability due to innovative measurement cell protection – even in corrosive or reducing conditions

- Reduction of analyzer failures due to internal self-monitoring

- No manual adjustment required

- Quick measurement close to the combustion process for timely control

- Approved for emission monitoring

- Easy analyzer operation – even remotely

Do you require a different solution? Please visit the manufacturer's website for more products!

SICK Official WebsiteSick GM35 In-Situ IR Gas Analyzer

Description & Features

Simultaneous or Individual Measurement of CO2, H2O, and CO or N2O

- Dynamic humidity correction

- Fast in-situ measurement directly in the process

- Simultaneous determination of up to three gas components, temperature, and pressure

- No gas sampling and conditioning

- Gas testable version of measuring probe available

- Integrated self-test and control functions

- Dynamic humidity measurement directly in the process

- Provision of real humidity reference values

- Unbiased measuring values due to in-situ measurement

- Fast or short-term fluctuations in the process are being detected

- Representative measurement by selection of an appropriate probe or cross-duct type